If you were fortunate enough to travel the globe, how many power adapters would you need to bring? The answer is 14.

Plugs, plugs, everywhere

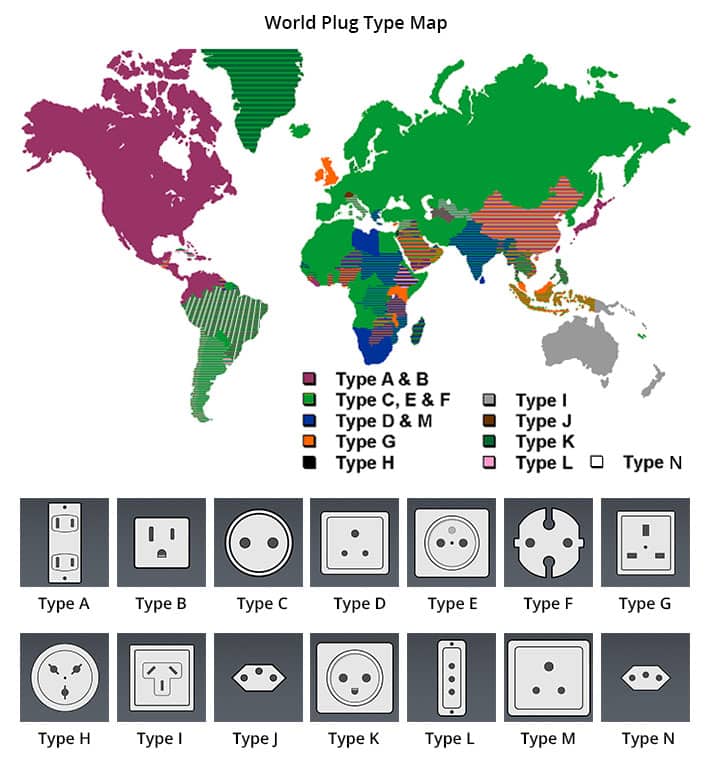

The world has 15 diverse types of electric plugs, labeled from Type A to Type O. Each country or region has a differently shaped plug, primarily due to voltage and frequency variations (Type O isn’t on the map below but is used exclusively in Thailand). With no initial international standards in place, each country forged its unique path, leading to the diverse plug types we see today.

Plug compatibility charts help ensure we use the appropriate plug type for each area, making it an essential tool for the modern-day traveler. For a fun fact, who would think that the eclectic continent of Antarctica would not have a standardized plug type? The type you’d find in any research station solely depends on who operates it.

That got us thinking. The electric plug scenario is peculiarly similar to a problem we’re facing right here at home – the truck driver shortage in the American trucking industry.

In our current trucking industry paradox, seasoned truck drivers are as unique as these plug types, and they are in high demand (when there’s not a freight recession). Several factors are contributing to a burgeoning problem.

The effects of the shortage

A driver shortage makes it hard for trucking companies to keep drivers on payroll because competitors are actively trying to lure them away. They don’t have a choice. Most trucking companies cannot hire newbies because most truck insurance policies won’t cover drivers with less than 2 years of experience. If a trucking company wants to expand, in most circumstances, it simply must hire drivers with experience. And those drivers are likely working for someone else already.

As a result, when a carrier grows, instead of adding a new driver to the industry, the growth creates a shuffling effect. Company A hires a driver from Company B. Now, Company B needs to hire a driver. They end up with one from Company C. And then they “poach” a driver from someone else. Rinse/repeat on down the line. If one new driver FTE were added, the chain would be broken. Instead, one created job leads to multiple job changes.

To attract quality drivers, trucking companies will use a signing bonus and higher pay rates. As competitors try to outdo each other, the cost for a trucking company goes up because those signing bonuses get pretty high and it’s really, really hard to implement new pay models designed to attract competitive talent without giving something better to existing drivers.

If a trucking company pays existing drivers more, its overall cost of driver operations goes through the roof. If it doesn’t, it’ll lose its veteran drivers. These costs will be passed on to shippers where possible. Where it’s not possible, the companies will operate at a loss until they go out of business.

Shippers will pass on costs to manufacturers who will increase the price of the product being shipped. Ultimately, the cost increase will be passed on to the consumer and the total bill paid will be inflated due to multiple layers. For what it’s worth, by our estimates, the shortage has already cost consumers over $50B in price hikes.

Operational effects

Operationally, a shortage also makes it hard for trucking companies to hire drivers as their job options are plentiful. This increases the time it takes for the trucking company to fill a vacancy. Longer job vacancies increase both real and opportunity cost, but they also interrupt the operational flow of the trucking operation. The longer it takes to hire drivers, the more loads will sit waiting for a driver to become available to deliver them. The worse the shortage gets, the longer it will take. Over a period of days, weeks, or months, a backlog of freight will build up.

This is where SlipSeat comes in.

Trucking companies can get a driver through us to use for the short-term so they can move loads and have happy customers. In areas with high concentrations of drivers working, it’s possible for a driver to be onsite within a couple of hours. We process DOT paperwork and payments in the background. When the work is complete or when the carrier is able to hire their own driver, the carrier and the SlipSeater unplug and go their separate ways.