“Thinking outside the box” is a vivid metaphor that encourages us to push beyond converse ideas or perspectives and look at situations in novel ways. It implores individuals to break free from the chains of traditional thinking, fostering innovation and offering groundbreaking solutions – an essential strategy, particularly in business environments, where fresh outlooks can break the monotonous cycle and propel growth.

The phrase is believed to emanate from a strategic nine-dot puzzle tool designed by psychologist Norman Maier to stimulate thought processes and used by management consultants in the 60s and 70s. They relied on this puzzle to train clients to stretch their thought process beyond perceived boundaries. It was, in a sense, like looking at a problem from an entirely new perspective, pushing clients to visualize novel solutions.

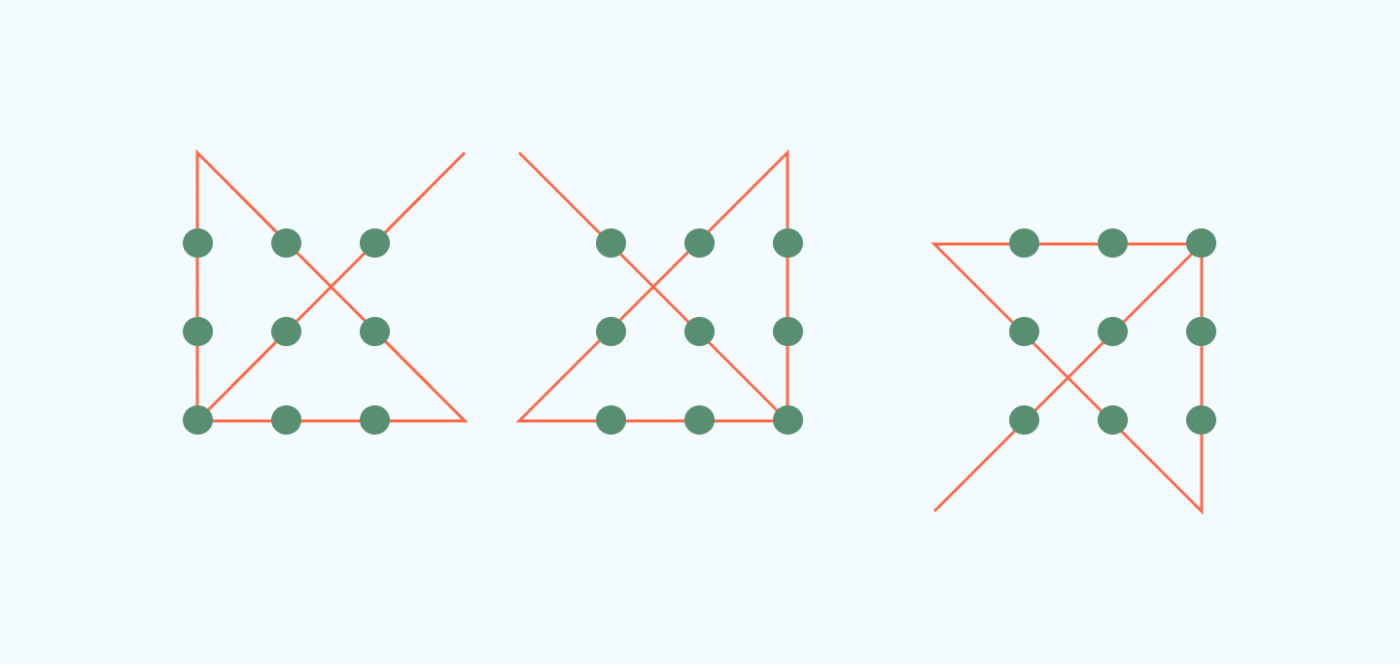

The structure of the nine-dot puzzle wonderfully encapsulates the concept of unconventional thinking. The challenge is simple, yet daunting; connect nine dots arranged in a square grid using four continuous lines without lifting your pen or retracing a single step.

The secret to solving this puzzle rests on one’s ability to push beyond perceived constraints.

According to Maier’s findings, most individuals fail to solve the puzzle as they unknowingly apply restrictive self-limitations. This puzzle cleverly illustrates that the key to innovative problem resolution lies in thinking beyond the confined space of the nine dots— a metaphorical allusion to out-of-the-box thinking.

There are a few different ways to solve the puzzle; likewise, there are different ways to use SlipSeat. The most profitable require a little out of the box thinking…

The Basics

Carriers come to us when they have loads sitting or have empty seats they need to fill. We connect them with drivers and owner operators for short term projects that don’t require training or the driver to wear a uniform.

But with a little out of the box thinking, SlipSeat is an innovative platform that streamlines the process of hiring and deploying drivers for motor carriers. By leveraging our services, carriers can reduce costs, optimize driver utilization, and enjoy greater flexibility.

Why limitations?

If carriers were to use 3rd party drivers for work where training or uniforms were needed (or in other ways treated the drivers as if they were internal employees), they might not be able to label the drivers as independent contractors during their work comp audit.

Carrier Onboarding

When a carrier comes aboard (it’s free), we ask a lot of questions about the drivers they use and the ways they use them. We also ask about their operations and how they run. Everything is held in the strictest of confidence. We add the carrier’s data to their local area data. Our system then recruits vendors off of the local area needs. When drivers sign up that match an individual carrier’s needs, the carrier will get an email.

Carriers who are hiring for positions can also create a job ad (free), and there’s a form in case the carrier knows any drivers who might make better 3rd party contractors than employees. Total elapsed time – maybe 20 minutes.

Optimizing SlipSeat

Each driver has a rate card attached to their profile. It’s per onduty hour. That’s the rate the carrier pays.

Once a carrier has used a driver for 100 hours, then we assume they like each other and add the driver to the carrier’s virtual driver team. When the carrier creates projects for drivers to bid, he’ll have the option to blast it to the entire team if he wants. His team can bid those any way they want – per mile, per load, per whatever.

So the carrier’s strategy becomes:

1) find drivers that look interesting either by creating projects, surfing drivers, or checking emails

2) If they’re good, use them for 100 hours (roughly 2 weeks) to add them to the team

3) Build up the team to increase the number of known drivers bidding on stuff, which in turn lowers the overall cost of driving projects

Optimizing Operations

If you have empty seats or are looking to save money, we recommend splitting your work into 2 buckets – core and flex. Your core bucket contains work that should be done by an employee. The flex bucket holds work that can be completed without training.

By creating two batches of work, you are creating the opportunity for two classes of drivers – flex and core. Starting with your core work bucket, assign a driver to each batch of core work. Then, do the same for flex work. When you run out of drivers to assign, find a SlipSeater. Specifically, look for ones that are open to full-time employment (we track that).

Pro tip: Because of how we’re setup, early adopters enjoy a first mover advantage where the system is recruiting drivers that match their needs. Even after other carriers join, the drivers will more than likely still be skewed towards the initial carrier.

Now, when a core employee quits, backfill them with a flex employee. When a flex employee quits or moves to core, backfill them with a SlipSeater.

Over time, you will end up with a core group of no fuss, long-term, dedicated employees with very little turnover and a flex group made up of SlipSeaters.

The benefits of this set up:

- Faster: Promoting from flex to core and backfilling the flex position can be accomplished in hours. There’s minimal operational disruption. The old way of hiring takes 2+ weeks.

- Cheaper (Front End): The new way is “free” (it’s included in our pricing). The old way has advertising, interviews which cost your time, screenings, signing bonuses, etc. A small carrier can easily spend upwards of $7500 with opportunity cost.

- Cheaper (Back End): Over time, your flex group will convert from W2 employees into 3rd party contractors, saving you social security payments, work comp, unemployment, and the cost of benefits.

- Safer: As the number of contractors increases, your accident exposure should fall (historically, carriers have been more exposed with employees than 3rd party drivers)

- Easier: Less workload for you. Can backfill flex drivers at 3am if you want.

- Fundamentally Better: With the old way of hiring, carriers don’t uncover fit until after the driver is an employee. Bad actors happen. This new way, carriers are able to evaluate drivers while they are contractors in the flex group before offering them W2 employment.

Optimizing Capacity Planning

Capacity planning is expensive and mistakes are pricey. Unfortunately it’s extremely difficult to get right because of the many unknowns. Our way is easier, less risky, and less costly for carriers. Drivers sell future capacity. We guarantee it – if they fail to show up, you can have your money back and we’ll help you find substitute capacity.

Some drivers will have a minimum commit. It’s a block of future capacity. Carriers can buy this and lock a driver in for a commit, example 100 hours per month for 6 months.

So when carriers get emails with drivers they like, they should reach out to those drivers. If they still like them, they should buy their capacity before a competitor does. Note, after 9 days of use, carriers should add SlipSeaters to their drug pool (per DOT) .

Conclusion

SlipSeat offers motor carriers numerous advantages in optimizing their driver utilization and reducing costs. By leveraging the platform’s features such as contractor teams, segmenting work, minimizing hiring costs, and streamlining onboarding and capacity planning, motor carriers can enjoy increased efficiency, lower expenses, and reduced risks. SlipSeat revolutionizes the way carriers both hire and work with drivers, creating a win-win scenario for both carriers and drivers.